How Did The PSS Seal Benefit The Kenosha Water Utility

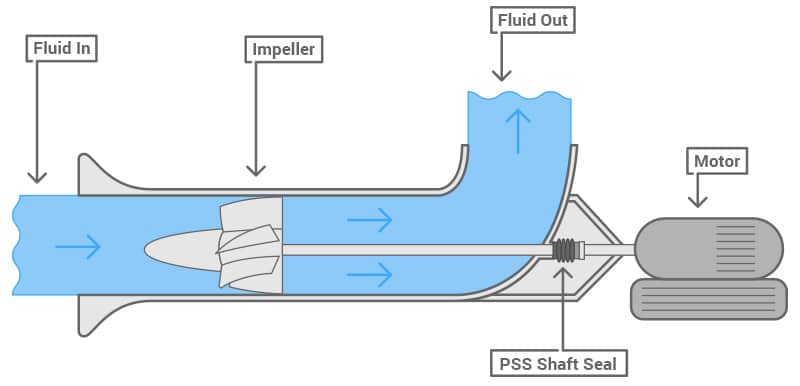

Kenosha Water Utility (KWU) has completed the PSS Shaft Seal retrofit of the old stuffing box type configurations on their mixing basin / horizontal mixer shafts at their water purification plant. KWU was looking for a solution to replace the constantly leaking and worn out traditional seals with something that will last, reduce cost, reduce pump down time due to seal maintenance and eliminate leaking, and the PSS Shaft Seal was their number one choice. PYI provided pressure resistant PSS Shaft Seals as well as mounting flanges for this retrofit project.

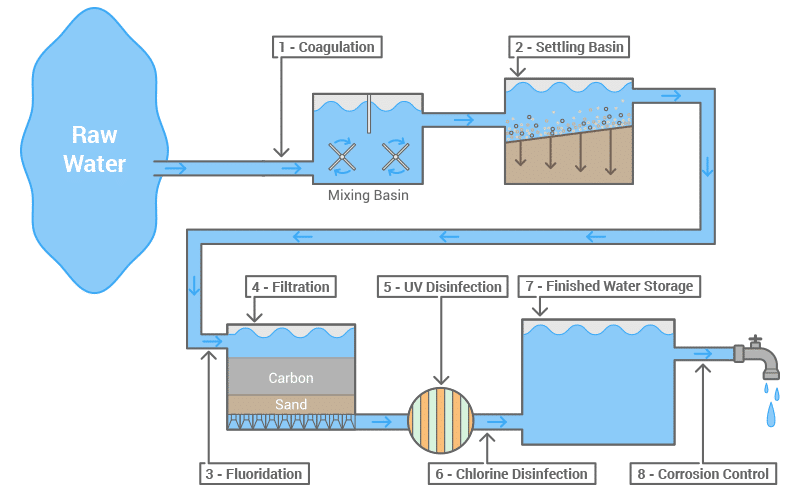

The water treatment system and PSS seals run 24/7 providing water to more than 110,000 persons in the greater Kenosha Metropolitan area, including the City of Kenosha, Village of Pleasant Prairie, Village and Town of Somers and Village of Bristol. The PSS Shaft Seal’s durability, reliability, simplicity, flexibility, ease of installation and maintenance along with PYI’s ability to customize mechanical sealing solutions in a very short period makes this a beneficial solution for any surface water utility using horizontal mixers on their flocculation / mixer basins. The Kenosha Water Utility team noted the installation "could not have been more straight forward, easy and resulting in very minimal down time".

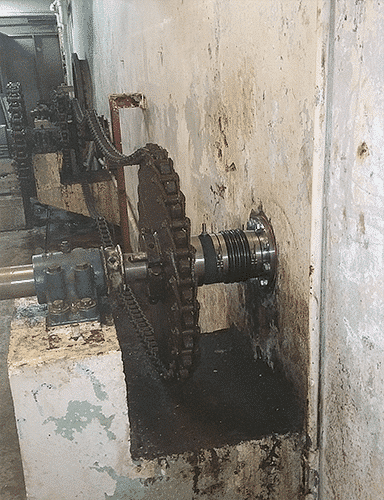

"The new seals eliminate the need for rope packing and the packing gland. In our case the stuffing boxes were worn out which made them hour glass shaped. Being there was more room inside the stuffing box than the packing could compress and make the seal the shafts leaked a lot. We used the old stuffing boxes as a mounting surface for the new flange. We also replaced all of the stub shafts from the outer pillow block bearings thru the wall to flanges inside the tank. The reason we replaced all of these were to provide a clean new surface for the PYI seals to be mounted on."

- Bob Wienke, Lead Operator